lead hardness test plans|cast lead hardness testing : supplier The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- tion, and the customer requirements. After process of elimination, there are often only a few options left.

Do not autoclave containers (except those made of fluoropolymers) containing detergent or wetting solutions. Note: Before autoclaving, just set cap or closure on top of the container without engaging .Not only can this disrupt the sterilization process inside the laboratory as the autoclave is cleaned and inspected, but the ruined material, glassware, and instruments could also cost hundreds or even thousands of dollars to replace.

{plog:ftitle_list}

Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial .

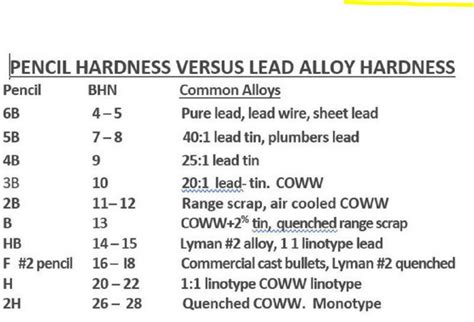

This describes a method for the determination of lead alloy hardness. It is a simple, quick, and economical means to test hardness of unknown alloys, and I have found it to be reliable and accurate.

I have one really good recommendation for a hardness tester that provides the . This describes a method for the determination of lead alloy hardness. It is a simple, quick, and economical means to test hardness of unknown alloys, and I have found it to be reliable and accurate. I have one really good recommendation for a hardness tester that provides the most versatile testing of lead alloys. It can be used with cast bullets, ingots, slabs, etc. It gives a BHN hardness result, which can be directly referred to. Homemade Lead Harness Tester. I work in a machineshop and I was able to come in after hours and fabricate a lead harness tester based on a short article in the Lyman cast bullet handbook 3rd edition. I will have a drawing and photos posted shrortly.

The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- tion, and the customer requirements. After process of elimination, there are often only a few options left. The cheapest way to do this is with the Lee Lead Hardness Testing Kit. It measures the “Brinnell” hardness of the alloy, which is simply a hardness scale relative to itself, and people have figured over the years how much pressure this hardness scale can correlate to.

lead hardness test chart

The hardness of a lead affects its strength, smoothness, smudge resistance, and pigmentation. Writers can use different lead grades to make their lines lighter or darker, while an artist can employ the full range of lead grades to achieve different effects.A 5-minute video covering the basics of cast bullet hardness and demonstrating Lee Precision's Lead Hardness Tester. In this video I have a little fun using various methods to measure the hardness of the lead alloys used to cast the bullets that will be used for this test. You can purchase the Lee Precision Lead Hardness Test Kit here: https://amzn.to/2IU98Vr

In this PounderLabs video we discuss Brinell hardness testing for metallic lead and its alloys, give some important history about Brinell and Meyer and how the LEE Precision Hardness. Test Hardness of Pure Lead. The hardness tester will only be accurate over the hardness range listed in the instructions. The indenter ball diameter determines the range over which the tester is accurate. This describes a method for the determination of lead alloy hardness. It is a simple, quick, and economical means to test hardness of unknown alloys, and I have found it to be reliable and accurate. I have one really good recommendation for a hardness tester that provides the most versatile testing of lead alloys. It can be used with cast bullets, ingots, slabs, etc. It gives a BHN hardness result, which can be directly referred to.

Homemade Lead Harness Tester. I work in a machineshop and I was able to come in after hours and fabricate a lead harness tester based on a short article in the Lyman cast bullet handbook 3rd edition. I will have a drawing and photos posted shrortly.

The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- tion, and the customer requirements. After process of elimination, there are often only a few options left. The cheapest way to do this is with the Lee Lead Hardness Testing Kit. It measures the “Brinnell” hardness of the alloy, which is simply a hardness scale relative to itself, and people have figured over the years how much pressure this hardness scale can correlate to. The hardness of a lead affects its strength, smoothness, smudge resistance, and pigmentation. Writers can use different lead grades to make their lines lighter or darker, while an artist can employ the full range of lead grades to achieve different effects.A 5-minute video covering the basics of cast bullet hardness and demonstrating Lee Precision's Lead Hardness Tester.

In this video I have a little fun using various methods to measure the hardness of the lead alloys used to cast the bullets that will be used for this test. You can purchase the Lee Precision Lead Hardness Test Kit here: https://amzn.to/2IU98Vr In this PounderLabs video we discuss Brinell hardness testing for metallic lead and its alloys, give some important history about Brinell and Meyer and how the LEE Precision Hardness.

lead hardness scale

Submersible polypropylene test tube racks sink in water baths and maintain stability even in agitated water. SP Scienceware™ No-Wire™ Autoclavable Test Tube Racks are a great alternative to wire racks, and are ideal for use in .

lead hardness test plans|cast lead hardness testing